Cryogenic Globe Valve refers to a valve whose disk moves along the center line of the valve seat.

1.Valve Size : 2 ~ 24”

2.Applicable Rating : ASME 150# ~ 1500#

3.Temperature : Down to -196 ℃

4.Code & Standard : BS, ASME, ASTM

Designed by BS6364, ASME B16.34, and ASME B16.25/16.5

5.Shell & Seat Leak Test : ASME B16.34.

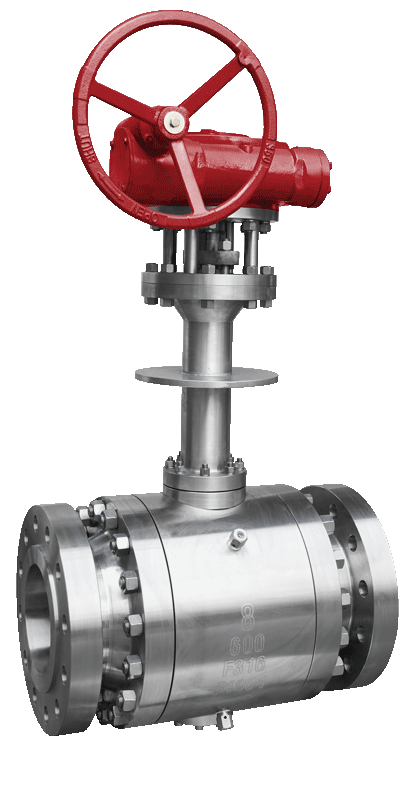

6.Constructions:

End Connection : Flanged, Butt-Welded or RTJ Type

Long Extended Bonnet

Operator : Gear-operated Type

Pressure Relief Design(Pressure Balance Design)

Fire Safety / Anti-static Design

1.The structure is simpler than the gate valve, and it is more convenient to manufacture and maintain.

2.The sealing surface is not easy to wear and scratch, and the sealing performance is good. There is no relative sliding between the valve disc and the sealing surface of the valve body when opening and closing, so the wear and scratches are not serious, the sealing performance is good, and the service life is long.

3.When opening and closing, the disc stroke is small, so the height of the stop valve is smaller than the gate valve, but the structure length is longer than the gate valve.

4.The opening and closing moment is large, the opening and closing is more laborious, and the opening and closing time is longer.

5. The fluid resistance is large, because the medium passage in the valve body is tortuous, the fluid resistance is large, and the power consumption is large.

6. The disc is often eroded when fully opened.

| PARTS NAME | MATERIAL |

| BODY | Cast Steel – ASTM A351-CF8(M)/CF3(M) |

| BONNET | Cast Steel – ASTM A351-CF8(M)/CF3(M) |

| SEAT | ASTM A276-304L(H.F) |

| DISK | ASTM A276-304(L)(H.F) / 316(L)(H.F) or Equivalent |

| STEM | ASTM A276-316(L) |

| GASKET | SPIRAL WOUND GRAPHITE |

| GLAND PACKING | GRAPHITE |

All metal parts are subjected to more than two deep cold treatments before finishing;

All extended valve stems (except check valves) are made of high-performance XM-19 or Inconel718 alloy materials;

All spheres are hardened and precision ground, with a surface accuracy of more than 0.2um;

All lip-seal seals are from international first-line brands;

All sealing surfaces that match the lip-seal are polished with precision technology to achieve a surface accuracy of more than 0.2um;

All "TEJI" brand cryogenic valves are tested for normal temperature and low temperature performance according to international industry standards before leaving the factory, and are shipped only after they pass the test;

All seals of the extended stem packing parts adopt a unique combined structure, which can not only ensure long-term sealing performance, but also reduce the switching torque;

All valves below -101℃ (except check valves) are equipped with cooling plates to effectively ensure that the temperature at the bottom of the packing is above 0℃; at the same time, it can effectively prevent condensed water from freezing on the valve body.

IMPROVEMENTS:

Welcome to Teji Valve Group Co.,Ltd. Get Updates And Stay Connected – Subscribe To Our Newsletter.

on your first order