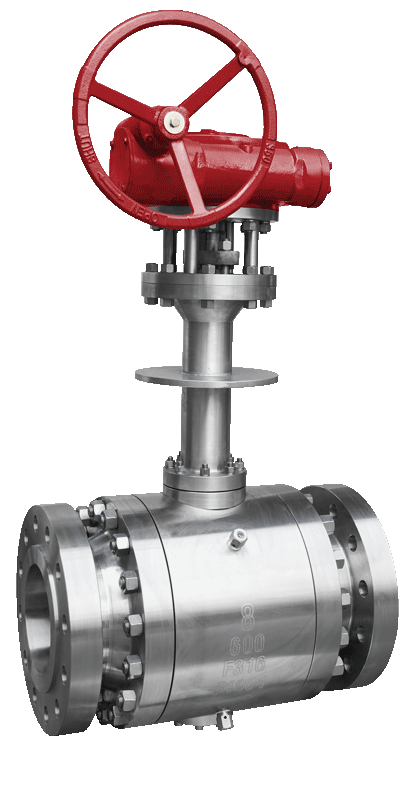

Cryogenic Double Block & Bleed Ball Valves are aimed to get a double barrier on the piping, and bleed the fluid trapped between the two balls from a dedicated drain line.

API 6D, API 6A, ASME B16.34, ISO 14313, ISO 10423, ISO 17292

-320.8 to 356°F (-196 to 180°C)

NPS 1”-12” (DN 25-300)

ASME Class150 – ASME Class2500

As per API 6D / GOST Standard / Customized Standard.

RF, RTJ as per B16.5 &B16.47

BW, Butt Welded as per B16.25

SW, Socket Welded as per B16.11

Stainless steel, Duplex and Super Duplex

Nickel alloys, Titanium

Forged bolted two-piece and three-piece, and Top Entry

Soft or metal seated with Hard facing on ball and seats

SPE / DPE

Combination seats

Double block and bleed design (DBB)

Secondary seals in pure Graphite

Anti-Static Device

Anti Blow out stem

Low fugitive emission stem packing available

Lip seals and Graphite configuration

CRA overlay on all dynamic sealing areas or on all wetted parts available

Extended bonnet for low temperature available

Manual: wrench or Gear with padlocking

Actuated: Pneumatic/ Hydraulic/Electric

Compliance with inspection and testing API 6D, ISO 5208,API 598,BS6364&MESC SPE 77-200

Fire safe and fire tested as per API 607/API6FA

SIL 3 Certification as per IEC61508

Fugitive Emission as per ISO15848

PED 2014/68/UE Annex III, Module H

DBBs are commonly used in the oil and gas industry, but can also be used in other industries where pipeline isolation is critical and no leakage occurs. These requirements are often required when dealing with high-pressure systems, toxic or hazardous media, and when isolation maintenance and calibration are required while keeping the rest of the piping system running. There are many applications in upstream and downstream offshore/onshore oil and petrochemical production, transmission and storage, and industrial processing of natural gas.

More specifically, DBB applications typically include bypass loops for instruments, such as flow meters or manometers, that need to be calibrated at defined intervals. Isolate upstream pressure, provide a backup seal, and release captured pressure for removal or work downstream where unpressurized. Due to the nature of the application, a second seal is desirable. Viscous and corrosive media can increase clogging and/or seal failure. A second isolation valve improves safety during routine maintenance operations. This is an important example of understanding the API definition and the intended use of a manufacturer’s product. The above applications should be met by using DIB valves, while DBB valves, such as trunnion ball valves with self-venting seals, have the potential for the first seal to leak and the exhaust valve to clog. This can cause the upstream pressure to overcome the spring to create a second seal, which can eventually damage the second seal. A popular solution is to use a self-operated ball, needle, or globe valve with an exhaust valve in the middle.

In conclusion, it is important to fully understand the definitions used to prescribe the type of valve, especially when dealing with pressure isolation. Proper use of large double shut-off bleed valves (DBB and DIB) can lead to a safer and more cost-effective piping system.

All metal parts are subjected to more than two deep cold treatments before finishing;

All extended valve stems (except check valves) are made of high-performance XM-19 or Inconel718 alloy materials;

All spheres are hardened and precision ground, with a surface accuracy of more than 0.2um;

All lip-seal seals are from international first-line brands;

All sealing surfaces that match the lip-seal are polished with precision technology to achieve a surface accuracy of more than 0.2um;

All "TEJI" brand cryogenic valves are tested for normal temperature and low temperature performance according to international industry standards before leaving the factory, and are shipped only after they pass the test;

All seals of the extended stem packing parts adopt a unique combined structure, which can not only ensure long-term sealing performance, but also reduce the switching torque;

All valves below -101℃ (except check valves) are equipped with cooling plates to effectively ensure that the temperature at the bottom of the packing is above 0℃; at the same time, it can effectively prevent condensed water from freezing on the valve body.

IMPROVEMENTS:

Anfeng Industrial Zone, Oubei Town, Yongjia County, Zhejiang Province

+86-0577-57799998

Welcome to Teji Valve Group Co.,Ltd. Get Updates And Stay Connected – Subscribe To Our Newsletter.

on your first order